Get in touch

with an expert

Send us your contact information and we’ll contact you.

In the food industry, food traceability is essential for ensuring the quality of products throughout the supply chain, from manufacturers to distributors.

REQUEST A QUOTE REQUEST A QUOTEWe deliver powerful marking and engraving solutions for industrial traceability—built for durability, backed by expert support.

Experience the Telesis difference today!

Food traceability requires reliable laser equipment for labeling, as it provides visible, durable markings on packaging that inform consumers about the product's value category. Additionally, it provides These markings also provide essential information about food protection, traceability, and shelf life.

At Vinssa, we offer specialized laser machines for food traceability that are efficient, reliable, and optimize your production system while maintaining the highest product quality.

Laser marking for food utilizes CO₂, vanadate, or ultraviolet (UV) laser technologies to engrave information such as expiration dates, logos, or serial numbers directly onto food products or their packaging. This non-invasive method only interacts with the surface layer of the food, preserving its quality, taste, and safety.

Some examples of foods that can be laser-marked include:

For containers such as glass, plastic, or Tetra Pak bottles, our bottle markers provide effective solutions for clear and precise identification.

These machines are ideal for engraving QR codes, expiration dates, and other traceability data, even on curved or difficult-to-mark surfaces.

Food traceability allows manufacturers and distributors to track products and ingredients throughout the supply chain, ensuring transparency and safety. It helps reduce the risk of foodborne illnesses and boosts consumer confidence.

Laser marking plays a key role in traceability by providing reliable, permanent labels, such as barcodes, serial numbers, and data matrix codes.

Integrating food traceability solutions into your production process offers the following advantages:

Laser marking plays a critical role in food packaging, where it generates essential traceability information. Here are three common applications:

QR Codes: A square grid code made up of pixel groups, providing easy access to digital information.

Barcodes: A series of parallel black-and-white bars representing characters and numbers. In the food sector, retailers use barcodes to track inventory, sales, and reorders.

Data Matrix Codes: Two-dimensional barcodes with black and white cells that store information across columns and rows.

Laser marking for food uses laser technology to engrave information directly onto food surfaces or packaging, such as expiration dates, lot numbers, and QR codes, without affecting product quality.

This method is sustainable, precise, and long-lasting. It eliminates the need for adhesive labels or ink, reducing costs and waste. The markings are also permanent and resistant to harsh conditions.

Laser marking is ideal for fruits like apples, oranges, mangoes, and lemons, as well as products like bread, cheese, eggs, eggplants, and potatoes.

Yes, it is completely safe. The process does not generate waste or use chemicals that could contaminate food. It only affects the surface layer, preserving product quality and safety.

Food traceability is the ability to track a product throughout the supply chain. Laser marking facilitates this process by engraving clear, permanent information for effective tracking.

Yes, bottle markers are ideal for engraving information on glass, plastic, or Tetra Pak bottles, ensuring precise labeling for liquids such as juices, dairy products, and oils.

Applications include engraving expiration dates, QR codes, logos, lot numbers, and other relevant data on fruits, vegetables, bread, cheese, and packaging such as bottles or cans.

The most common laser types are CO₂, ultraviolet (UV), and vanadate. Each is suited to different materials and marking needs based on the food product or packaging.

As an automated process, laser marking reduces production times, ensures precision, and minimizes labeling errors, optimizing the entire supply chain.

A company needs a suitable laser marking machine, such as the Telesis models available at Vinssa, and a process aligned with food traceability regulations to ensure safety and compliance.

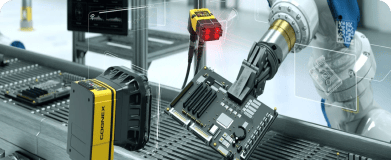

We offer custom industrial artificial vision systems for the identification of parts, materials, production defects, and barcode reading for process traceability.

Industrial robot solutions that ensure productivity and quality on your production line.

Industrial vending machines provide inventory management for supplies and tools, reducing costs and increasing your company’s productivity.

Únete y sigue nuestros artículos, promociones y novedades.