Get in touch

with an expert

Send us your contact information and we’ll contact you.

Copper stands out from other metals due to its excellent heat conductivity and high durability. Its marking requires special attention to ensure precision and effectivenes.

Request a Quote Request a QuoteWe deliver powerful marking and engraving solutions for industrial traceability—built for durability, backed by expert support.

Experience the Telesis difference today!

Copper is a reflective metal with low light absorption, which is why special machinery is needed for its marking. It is also known as a semi-precious metal, characterized by its easy processing and high durability.

Yes, it is possible to mark copper and brass surfaces with a laser when the appropriate marking system is used. The process involves the laser beam removing material from the copper and/or brass surface to create precise , deep etching. As a result, clear, permanent marks are achieved.

Laser marking on copper and brass has a wide range of applications. Here are some examples:

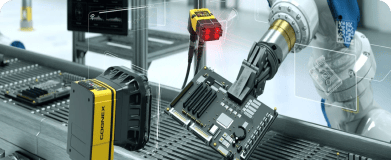

We offer custom industrial artificial vision systems for the identification of parts, materials, production defects, and barcode reading for process traceability.

Industrial robot solutions that ensure productivity and quality on your production line.

Industrial vending machines provide inventory management for supplies and tools, reducing costs and increasing your company’s productivity.

Únete y sigue nuestros artículos, promociones y novedades.