Habla con

un asesor

Envíanos tus datos y nos pondremos en contacto contigo.

Industrial metal tag machines, metal tag printers, and custom solutions for manual and automatic identification.

Contact Us Contact UsAt VINSSA, we collaborate with InfoSight, a global leader in industrial identification tecnologies, to bring cutting-edge solutions. To metal tags and label printers to custom machinery, we provide tailored identification systems that withstand the harshest industrial enviroments.

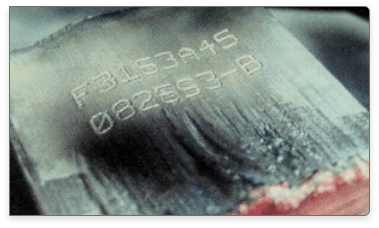

High-contrast metal tags for steel plate identification. Durable tags that that can be securely attached using MIG welding, rivets, or strapping -ideal for extreme environments.

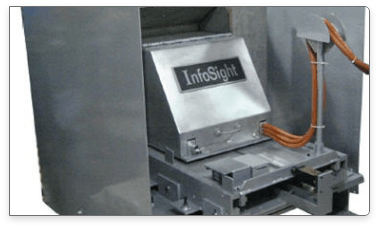

The InfoDent® ID8400 system is a programmable solution for the steel industry ,capable of marking hot or cold parts with precision and permanence.

Stamping systems. Designed for fast and robust marking on the ends of steel ingots of bars- hot or cold.

Automated systems ensure accurate identification, of high-temperature products with automated print-and-apply mechanisms.

Metal tags engineered to endure intense heat and maintain legibility through cooling and final processing.

New high-contrast laser marking technology for traceability in automotive manufacturing.

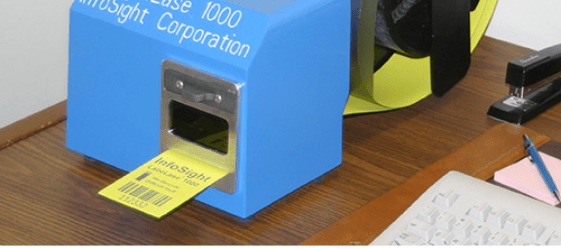

InfoSight’s I-Dent® ink printing system. Cost-effective manual marking solutions for general industrial use-efficient, reliable, and easy to operate.

Specialized in metal tags with barcodes or datamatrix, designed for extreme conditions where identity, tracking, and traceability must not fail.

Trusted in global industries including: steel & aluminum, Automotive, Galvanization, Glass, rubber, tire, wood and pipe manufacturing.

Resistant to heat, corrosion, abrasion, humidity, and chemicals.

LabeLase® Printer Features:

Resist oxidation, acids, humidity, and abrasion

Laminated and durable labels for painting lines.

Designed for use in steel processing and heat treatment.

Highly effective for heat treatment processes.

Ideal for high-contrast markings requiring superior durability.

challenge: A steel company in Nuevo León, with more than 500 employees, had a four-day cooling process for its products. This caused disruptions to the organization due to the lack of identification of casting dates for each of these products.

Solution: A JM-410 printer was provided with Xtag labels for barcode identification, which enabled product traceability as well as automation in data collection, since the label information arrives via Ethernet communication.

Únete y sigue nuestros artículos, promociones y novedades.