Get in touch

with an expert

Send us your contact information and we’ll contact you.

Consultancy to choose the right adhesive for your projects, with supply plans for your production lines and maintenance areas.

Request a quote▸ Request a quote▸

Industrial adhesives are designed to join materials with a strong, durable, and clean bond- especially where traditional fastening methods like screws or welding could damage the part´s structure or appearance.

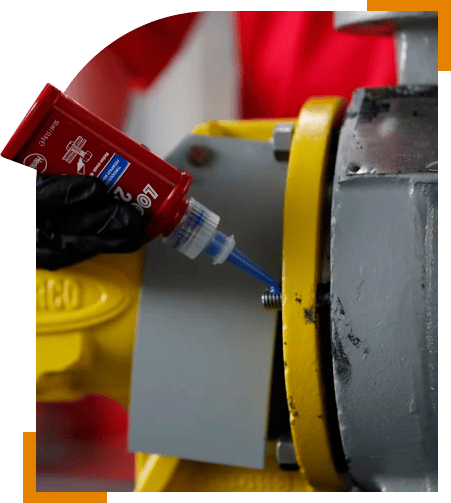

As a product used to seal materials, LOCTITE® adhesives compete with other joining techniques such as welding, mechanical joints, friction joints, hybrid joints, etc., Adhesives not only simplify assembly but also extend product life by evenly distributing loads, reducing stress points, and resisting environmental challenges like heat, moisture, and vibration.

At Vinssa , we offer a wide range of LOCTITE® adhesives designed for specific industrial needs:

Joining independent components during assembly

Sealing flanges and other elements that require airtight, watertight integrity.

Fixing screws to prevent loosening from vibration and wear

Manufacturing and assembling consumer and industrial products.

Bonding metal plates and sheet metal panels in construction.

Serving industries like medical, mechanical, furniture, office and more.

Playing a vital role in aeronautics for aircraft, helicopters, and rockets

Manufacture of units in the automotive industry, in areas such as interior upholstery, joining of dashboard parts, doors, accessories and other components.

LOCTITE adhesives are available in a variety of formulations to meet the demands of different applications

Each LOCTITE adhesive is designed with specific properties to suit differente materials and conditions. Selecting the right adhesive depends on the materials to be bonded and the environment they´ll be exposed to. I you´re unsure, contact us- our expert advisors are ready to help you find the perfect solution for your design, process, or industry.

LOCTITE adhesives offer a range of benefits, including:

There are different types of LOCTITE instant adhesives suitable for applications requiring impact resistance, flexibility, gap filling, low odor, extremely fast curing, thermal cycle resistance and high temperature resistance, cytotoxicity certification, etc., along with a wide range of viscosities.

LOCTITE adhesives are used to bonda wide range of materials- including rubber, polystyrene, wood, metal, and advanced plastics in seconds. With different viscosities and formulations, there´s always a LOCTITE adhesive suited for gap filling, sealing, or conventional bonding, no matter the application.

LOCTITE offers several technologies for instant bonding, including cyanoacrylates, UV light-cured adhesives, hot melt, solvent-based, and specialty adhesives. Each technology is designed for specific use cases and application. For personalized advice, contact our experts.

LOCTITE adhesives are suitable for a wide range of plastics, including difficult-to-bond surfaces like polypropylene and polyethylene (just to name the most common ones). They provide fast, strong, and flexible bonds, with gap-filling and two-components options available - designed for manufacturers who rely on plastic components in their production processes.

LOCTITE adhesives for metals are ideal for bonding or repairing mechanical parts, components, appliances, and industrial parts. They offer fast curing, excellent weather and humidity resistance, and strong, durable bonds- all without the need for clamping.

LOCTITE adhesives are designed to handle the challenges of bonding rubber materials such as nitrile, butyl, silicone, EPDM, and natural rubbers. These adhesives cure quickly, maintaing flexibility, and prevent cracking or separation over time, making them ideal or both manufacturing and general maintenance.

Already know which product you need?

Browse our supply store to order now!

Or

Not sure which adhesive fits your project? Our team of experts is ready to help you select the best solutions for your process. Contact us today!

Únete y sigue nuestros artículos, promociones y novedades.