Get in touch

with an expert

Send us your contact information and we’ll contact you.

We offer high-precision cycloidal Nabtesco gears in various configurations, tailored to meet specific application needs.

Contact Us▸Our high-precision cycloidal gears provide excellent performance and long service life. Our service team ensures fast delivery, short response times, and professional commissioning to integrate your systems smoothly and efficiently.

RS gears are specifically designed for reliable and precise positioning of heavy loads up to 9 tons. The cast iron base ensures stable and durable floor mounting. Their high performance and precision make them superior to conventional helical gears.

Gear reducers (based on RV gear sets) designed for high output speeds, making them ideal for robot axis automation, machine tools, and conveyor systems.

Nabtesco’s Cycloidal Gear technology is the far superior choice when compared to traditional planetary and cam indexing devices.

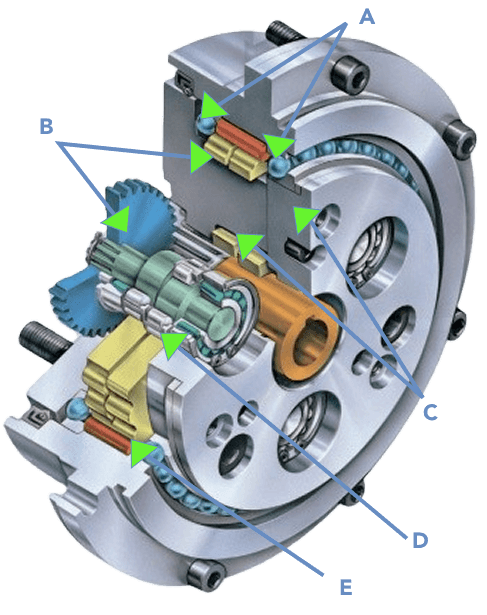

The Nabtesco Reducer consists of a patented two-stage cycloidal design that provides large torque, high-ratio and significant shock-load capabilities with extreme precision and excellent quality. The RV gear utilizes rolling contact elements to reduce wear, extend life and lower backlash with the unique pin and gear structure of the cycloidal design providing higher shock resistance than traditional reducers and further reducing backlash.

The reducer also incorporates a set of large, internal angular support bearings that provide large moment capacities and negate the need for external support devices

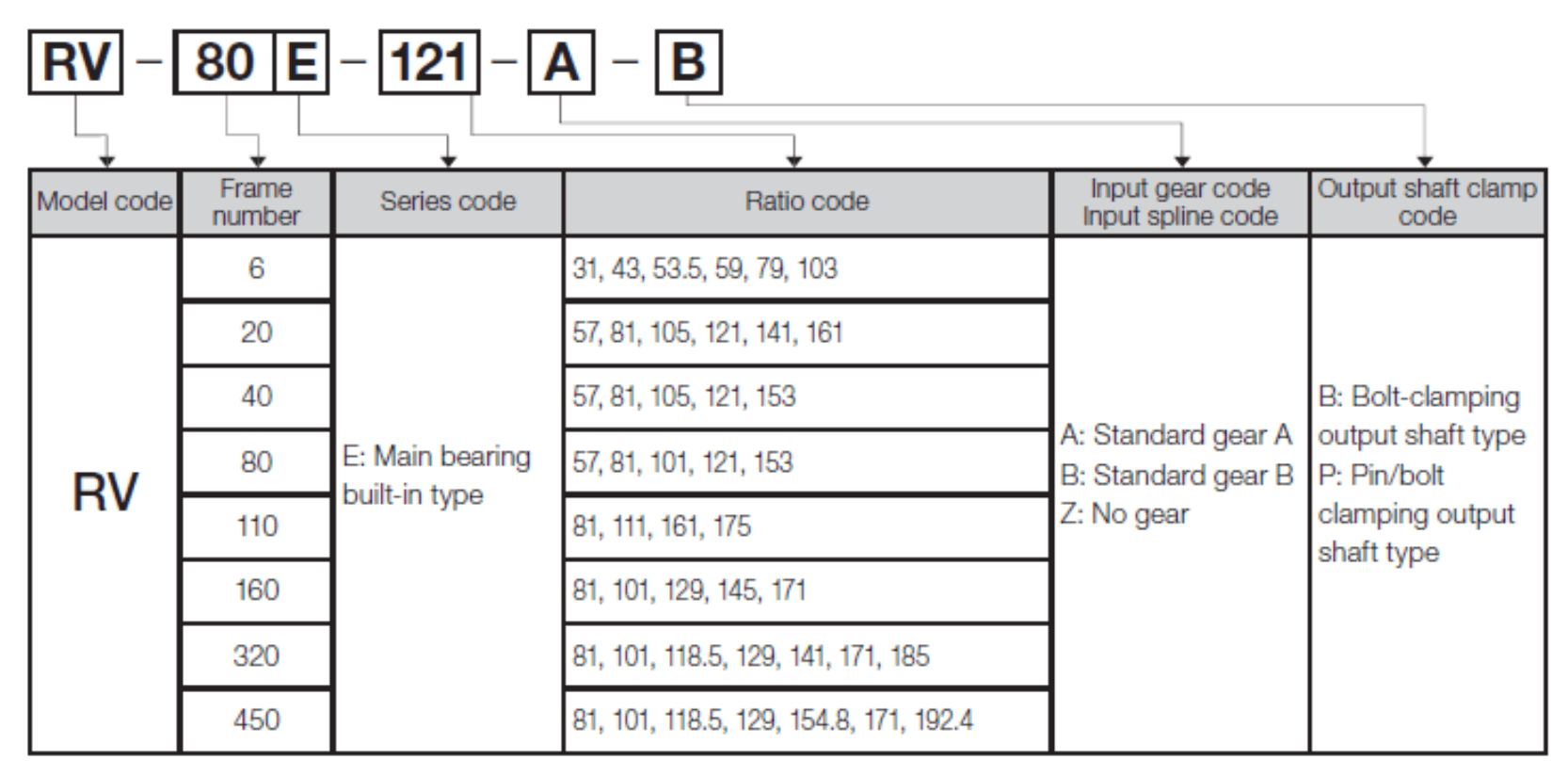

By sharing these product codes with us, we can quickly identify the ideal Nabtesco gearbox for your needs and provide you with an accurate and timely quote.

Contact us for specialized consulting. We can help bring even the most complex projects to life with the ideal Nabtesco solutions.

We also offer customized Nabtesco gearboxes fully tailored to your needs, with the expertise to implement all requirements quickly and professionally.

The RV-C series features a hollow shaft with a diameter of up to 138 mm, allowing for data cable and power line routing.

The RV-N series is a highly compact, lightweight, and high-performance solid shaft gearbox, perfect for applications with limited space requiring high torque performance.

Adjusting large parabolic antennas for communication with Earth-orbiting satellites.

Highly dynamic pick-and-place applications with SCARA and Delta robots.

For driving and handling very large loads.

Delta, SCARA, and 6-axis robots for painting systems, assembly, PCB handling, and machine tools.

Imaging processes such as X-rays, MRIs, and ultrasound examinations.

Pick-and-place, palletizing, and food industry applications.

Positioners and rotary tables for precise part alignment.

For photovoltaic installations, solar thermal systems, and entral receiver power plants.

Blade pitch and azimuth drive systems for onshore and offshore wind turbines.

Loads

Ratios

Accuracy

Maintenance

Things to consider when choosing a Gearbox. After many years developing Cycloidal Gears our engineers have created some basic questions to help you in the beginning steps of selecting a gearbox for your application.

Únete y sigue nuestros artículos, promociones y novedades.