Get in touch

with an expert

Send us your contact information and we’ll contact you.

Laser marking in the automotive industry ensures the quality and efficiency of parts by guaranteeing traceability, enhancing brand attributes, and ensuring customer satisfaction.

Request a quote Request a quoteWe deliver powerful marking and engraving solutions for industrial traceability—built for durability, backed by expert support.

Experience the Telesis difference today!

Different laser types are used in the automotive industry depending on the material and application:

Ideal for metals such as stainless steel and aluminum, known for high power, speed, and deep marking capability. (XpressMark MOPA, APEX 200, Summit Pro, Dual-Head)

Provides high-precision marking on electronic and delicate plastic parts without heat damage, ideal for crisp micro-marking. (UV/KYRO y UV/One)

Mainly used on plastics, leather, and organic materials, suitable for heavy-duty tasks and labeling.

Recommended for reflective or heat-sensitive materials, operates without generating harmful heat, protecting precious metals and electronic components. (EVCDS)

Laser marking in the automotive industry is essential for the durability and quality of products, as they must withstand use and time. Industry professionals understand the importance of ensuring both product and buyer safety, as laser marking sustains production traceability while ensuring the quality of each part.

Telesis offers the latest technology in automotive laser marking machines to improve your company's performance. Designed to provide the quality, resistance, and durability your products require.

Traceability involves tracking every step in the manufacturing process of a product. In the automotive industry, this is vital because vehicles are made up of numerous components, sourced from different suppliers. Laser marking plays a key role in ensuring that each part functions as expected by clearly marking them with identifiable codes.

These marking systems enable manufacturers to engrave unique codes, including Vehicle Identification Numbers (VIN), security codes, and 2D matrix codes on automotive parts. Our laser marking systems create high-precision engravings on each component, ensuring readability and visibility for accurate tracking.

Automotive laser marking machines engrave various identification codes that support traceability processes. These include:

Data Matrix Codes: Square or rectangular patterns of black and white marks containing encoded information.

Vehicle Identification Numbers (VIN): Unique 17-character codes identifying a vehicle’s manufacturer and features.

Barcodes: Parallel black and white bars used for automated part tracking in supply chains.

Serial Numbers: Engine Serial Numbers (ESN) that indicate engine type, manufacturing date, and location.

Laser marking in the automotive industry is a permanent identification technology that uses a focused light beam to engrave information directly on metal, plastic, or electronic parts. This process guarantees traceability throughout the component’s life, ensuring quality and compliance with international standards

Laser marking operates by focusing a high-energy light beam onto a part’s surface. The energy heats, oxidizes, or removes a thin layer of material, producing a visible and permanent mark without physical contact.

In the automotive sector, this technique marks serial numbers, 2D Data Matrix codes, logos, or safety data on critical components such as chassis, engines, and sensors.

An automotive laser marking system consists of several key components:

Telesis is globally recognized for the durability, precision, and reliability of its laser and dot peen marking equipment. Their technology is engineered for the most demanding automotive manufacturing environment, providing high resistance to vibration, dust, and temperature fluctuations. Additionally, the Merlin® software enables seamless integration with automated production systems, reducing human error and boosting efficiency.

As an authorized Telesis distributor in Texas, VINSSA, helps automotive plants implement reliable, fully traceable marking solutions that meet top quality and productivity standards.

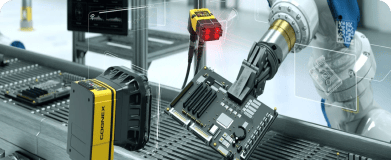

We offer custom industrial artificial vision systems for the identification of parts, materials, production defects, and barcode reading for process traceability.

Industrial robot solutions that ensure productivity and quality on your production line.

Industrial vending machines provide inventory management for supplies and tools, reducing costs and increasing your company’s productivity.

Únete y sigue nuestros artículos, promociones y novedades.