Get in touch

with an expert

Send us your contact information and we’ll contact you.

Stainless steel is the most widely used material in the industry due to its durability and resistance. The Telesis marking systems are specialized for laser marking on steel due to its characteristics.

Request a quote Request a quoteWe deliver powerful marking and engraving solutions for industrial traceability—built for durability, backed by expert support.

Experience the Telesis difference today!

There are different types of laser marking equipment for stainless steel, each with specific features depending on the application.

The most common for stainless steel, it offers excellent beam quality, ideal for deep engraving, annealing, or marking 2D codes. Typical applications include automotive components, tools, and medical parts. Equipment: XpressMark Series, APËX 200, F Series

Ideal when a clean, burr-free contrast is required; recommended for high-precision markings without affecting the metal’s structure. Common applications include electronic devices and small parts.

Although mainly used on non-metallic materials, it can mark stainless steel with a special coating or through assisted processes. Typical applications include packaging or treated surfaces.

Stainless steel, known for its versatility, durability and corrosion resistance, is widely used in industries such as medical, aerospace and food. We Highlight the advantages of laser marking on steel to give you a broad perspective on its applications.

Laser marking on steel preserves the surface of the product being marked. The stainless steel laser marking machine used is specifically designed to remove only the necessary surface material with high precision.

So, the answer is no—laser marking does not damage the stainless steel surface. Instead, it ensures a meticulous and precise marking process.

There are numerous benefits to using laser marking on steel, including:

Laser marking is essential for enhancing production and distribution efficiency across industries. Common applications include:

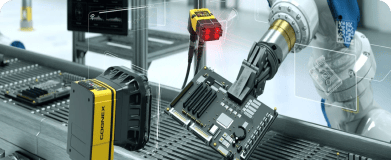

We offer custom industrial artificial vision systems for the identification of parts, materials, production defects, and barcode reading for process traceability.

Industrial robot solutions that ensure productivity and quality on your production line.

Industrial vending machines provide inventory management for supplies and tools, reducing costs and increasing your company’s productivity.

Únete y sigue nuestros artículos, promociones y novedades.