Get in touch

with an expert

Send us your contact information and we’ll contact you.

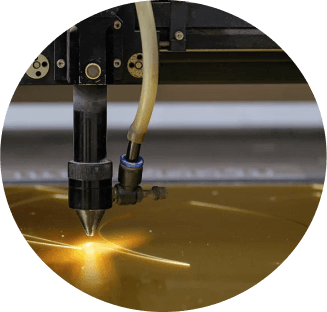

Laser marking on plastics is essential for your business as it enhances return on investment (ROI) and reduces manufacturing labor costs. This technology allows businesses to expand into new markets and enhance their competitive advantage through improved results.

Request a quote Request a quoteWe deliver powerful marking and engraving solutions for industrial traceability—built for durability, backed by expert support.

Experience the Telesis difference today!

Laser marking on plastics is essential in various industries, as it improves product traceability and meets the specific needs of multiple applications.

The most commonly used systems for laser marking on titanium are:

Recommended for plastics with additives or pigments. Enables high speed carbonization or ablation processes.

Excellent for delicate or heat-sensitive plastics. Produces clean marks without burning or deforming the part.

Ideal for transparent or hard-to-mark plastics such as PET or acrylics.

High-precision laser marking on plastic surfaces offers numerous benefits to your production process. Here are the key benefits:

Carbonization: The longest process, working with polymers, biopolymers, and organic materials like leather and wood, resulting in high carbon concentration.

Color Change or Toning: Removes pigmented macromolecules through an electrical process for high readability..

Ablation: Eliminates thin layers and coatings from the base material.

Expansion: This process reaches a boiling point, creating vaporized bubbles and producing a raised marking effect.

Laser marking on plastic is a process that uses a concentrated beam of light to create marks such as codes, text, and/or symbols directly on the material’s surface. Unlike traditional methods, laser technology produces permanent, clean, and durable marks, making it ideal for industrial applications that require traceability, quality, and long-term performance.

This process does not require inks, chemicals, or direct contact, which reduces maintenance costs and increases precision.

Yes. The laser can mark, engrave, or change the color of plastic, depending on the material and the technology used. The laser produces permanent, clean, and durable marks for applications in automotive, electronics, medical, consumer, and other production lines. Laser engraving does not affect the structural integrity of the plastic and offers superior precision, even on small or complex parts.

Most industrial plastics can be laser marked, as long as the appropriate technology is selected:

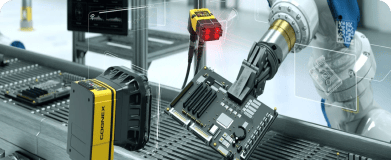

We offer custom industrial artificial vision systems for the identification of parts, materials, production defects, and barcode reading for process traceability.

Industrial robot solutions that ensure productivity and quality on your production line.

Industrial vending machines provide inventory management for supplies and tools, reducing costs and increasing your company’s productivity.

Únete y sigue nuestros artículos, promociones y novedades.