Get in touch

with an expert

Send us your contact information and we’ll contact you.

Titanium is a versatile metal known for its shine, corrosion resistance, and durability. Discover our Telesis Laser Marking Titanium solutions, ideal for various applications.

Request a quote Request a quoteWe deliver powerful marking and engraving solutions for industrial traceability—built for durability, backed by expert support.

Experience the Telesis difference today!

Titanium is a lightweight, durable, shiny, metal that resists corrosion.. Its use in various industries is crucial, as it withstands more than any other metal component. One challenge some companies face is laser marking titanium. However, at Vinssa, we offer specialized marking systems for titanium surfaces.

The most commonly used systems for laser marking on titanium are:

Ideal for deep engraving and well-defined marks such as Data Matrix codes, serial numbers, logos, and more. Recommended laser systems include: XpressMark MOPA, Summit Pro, and Apex 200 form Telesis

Perfect for very small marks, fine details, microcomponents, or areas where minimal heat impact is required. Recommended laser systems include: UV/One and UV/KRYO.

Excellent for achieving high contrast, especially when the titanium has a coating or has been previously anodized. This technology tends to change the surface color without removing much material, resulting in a visible mark without deep damage.

Other systems that may be used for specific titanium applications:

The E-Series is highly effective for heat-sensitive materials and applications requiring exceptional beam quality

Allows two laser heads to be operated from a single controller, increasing productivity for repetitive marking or high volume production lines.

Yes, titanium can be laser marked. However, a specialized marking system is required. The process involves a laser beam precisely removing surface material, creating deep and permanent markings. Another method focuses the laser beam on the titanium surface, designing the marking without removing any material.

Laser marking on titanium offers several advantages:

Traceability in industries using titanium components is essential for enhancing production and distribution quality. Laser marking allows the following applications:

Titanium is widely used in industries such as aerospace, medical, and automotive, where strength, durability, and light weight are essential. Laser marking is an ideal solution, as titanium responds exceptionally well to the laser beam, allowing for permanent markings with sharp, readable, and high-precision contrast without compromising the integrity of the material.

Laser marking in titanium is widely used across industries where product identification and traceability are essential. Thanks to its durability and excellent laser response, titanium is ideal for high-performance applications such as:

Titanium offers an excellent response to the laser beam. This material can be marked, ed, or anodized using laser technology, allowing for clear, readable con that are resistant to abrasion, corrosion, and high temperatures.

Fiber laser systems provide precise control over power, frequency, and speed, making it possible to achieve everything from deep engravings to shallow surface marks with color changes.

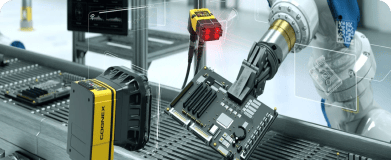

We offer custom industrial artificial vision systems for the identification of parts, materials, production defects, and barcode reading for process traceability.

Industrial robot solutions that ensure productivity and quality on your production line.

Industrial vending machines provide inventory management for supplies and tools, reducing costs and increasing your company’s productivity.

Únete y sigue nuestros artículos, promociones y novedades.