Get in touch

with an expert

Send us your contact information and we’ll contact you.

Optimize your production line with Cognex vision systems and verifiers to enhance product quality.

Request a quote Request a quoteCognex is a global leader in machine vision technology, renowned for its high-performance deep learning capabilities and unmatched quality in industrial vision systems.

Boost your productivity with these key benefits such as:

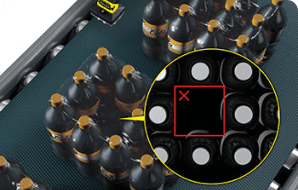

Cognex vision systems identify defects and flag errors before products reach the customer, safeguarding your brand and reducing rework. Key benefits include:

Cognex vision systems inspect food containers and packaging to ensure completeness and integrity. Key benefits include:

Prevention of contamination and spills.

Detection of damaged or incomplete packaging.

Safeguarding your brand reputation.

Reducing returns from wholesalers and retailers.

Vision-guided inspections ensure product integrity and consistency at every stage. Applications include:

Cognex barcode readers and vision systems guarantee correct labeling on food and beverage products, prevent packaging errors, and make defect tracking easier.

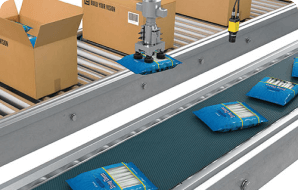

Manufacturers must enhance production, quality, storage, and distribution management. With Cognex, your operations become faster, more accurate, and more efficient in warehouses and distribution centers. Applications include:

Únete y sigue nuestros artículos, promociones y novedades.