Get in touch

with an expert

Send us your contact information and we’ll contact you.

The all-in-one solution that tackles 3D inspection applications as easily as 2D

Contact Us Contact UsCognex is a global leader in machine vision technology, renowned for its high-performance deep learning capabilities and unmatched quality in industrial vision systems.

The In-Sight® 3D-L4000 is a revolutionary advancement in three-dimensional (3D) vision technology. This system integrates 3D laser displacement technology with a smart camera, enabling fast, accurate, and cost-effective inspections across a wide range of automated production environments.

The patented blue laser optics in the 3D-L4000 series deliver higher-quality images outperforming conventional 3D laser systems. This advanced technology minimizes speckle and glare, which are common issues in traditional 3D laser systems.

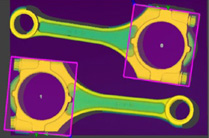

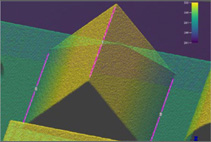

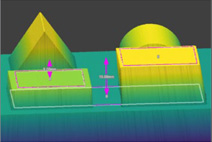

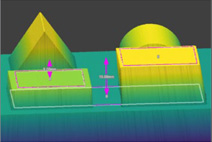

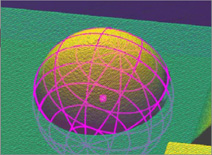

Unlike traditional 3D systems that convert 3D into 2D height maps, the In-Sight 3D-L4000 applies vision tools directly on a true 3D image ,improving accuracy and expanding inspection possibilities. Since inspections are performed on the actual 3D component, users can instantly observe how vision tools interact with the real piece.

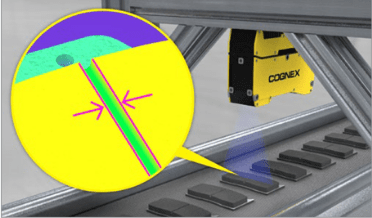

Measure spacing and inspect beveled edge angles of brake pads.

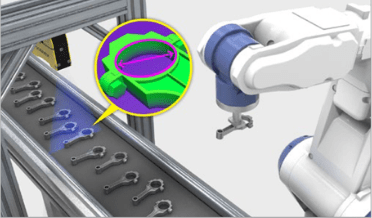

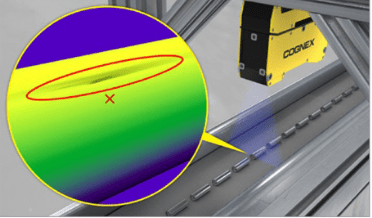

Locate and measure with PatMax 3D to ensure defect-free parts.

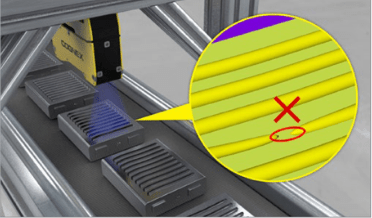

Analyze height, width, volume, and continuity.

Detects handling marks, scratches, and surface defects.

Locate joint edges and verify proper placement on tires.

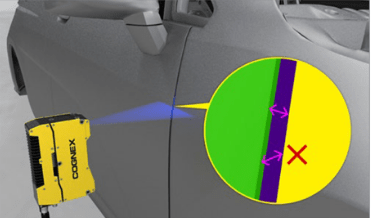

Ensure proper spacing body panels, maintaining consistent gaps.

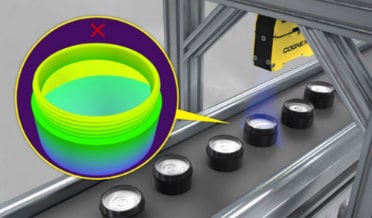

Verify cap presence and position by checking height and tilt to confirm proper threading.

Measure fill height and volume to ensure containers have the correct amount of product.

Inspect floor sheets for orientation via tabs and detect defects such as nicks, warping, indentations, and knot voids.

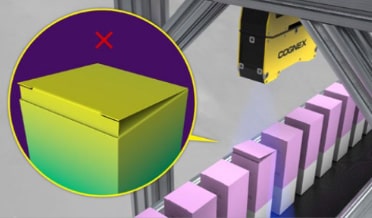

Verify intact and sealed boxes, checking for quality issues like crushed corners, tears, or open flaps.

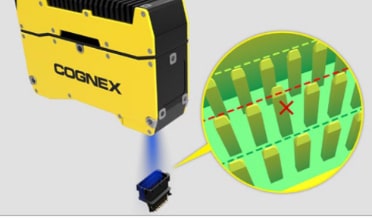

Validate pin count and alignment, ensuring no damage or bending.

Check chip placement accuracy

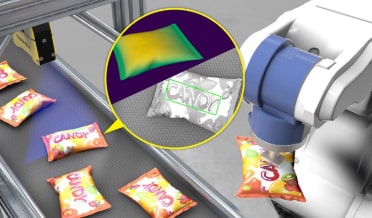

Locate flexible food bags on conveyors, identify orientation using combined 2D/3D tools, and inspect volume for defects; relay orientation data to packing robots.

Confirm part presence and volume.

Measure cookie length, width, height and inspect for cracks.

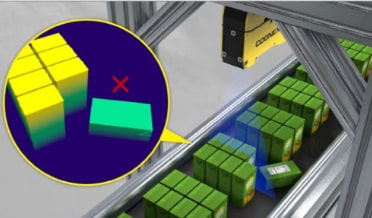

Ensure correct count and orientation of packages, verifying none have fallen and packaging is free of damage.

Validate bottle cap height and position.

High-quality marking processes for automotive parts with minimal downtime, operating 24/7 all year round.

Marking of circuit boards to identify their components.

Verification of expiration dates and batch codes on vaccines and medications, ensuring compliance with necessary regulations.

Verification of expiration dates and batch codes on food and beverages, ensuring regulatory compliance.

Improving manufacturing quality and performance of consumer products with vision systems.

Long-distance code detection.

Inspection of assemblies with very small dimensions.

Únete y sigue nuestros artículos, promociones y novedades.