Get in touch

with an expert

Send us your contact information and we’ll contact you.

Ensure safety, compliance, and quality with Cognex vision and verification systems.

Request a quote Request a quoteCognex is a global leader in machine vision technology, renowned for its high-performance deep learning capabilities and unmatched quality in industrial vision systems.

Cognex machine vision automates inspections and code reading, ensuring regulatory compliance for medical devices. The medical industry must meet the highest standards of quality and delivery. Therefore, inspecting packaging integrity and maintaining detailed records of production outcomes, both successes and failures is critical.

Cognex vision and verification systems are perfectly suited for these tasks, offering reliable and accurate detection of packaging defects. Each solution is engineered to meet the precision demands of pharmaceutical and medical device manufacturing.

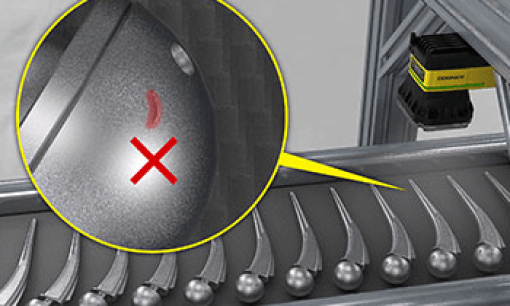

Cognex machine vision detects microscopic surface defects, dents, and contamination that could pose risks to patients. Medical products come in various shapes, sizes, and materials—from reflective metal implants to fine mesh devices.

Since these items are used on or implanted in the human body, it is essential to use advanced.

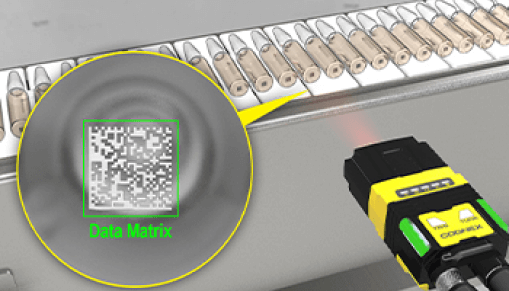

Cognex barcode readers use advanced image-based and OCR machine vision technology to accurately scan devices of various sizes and shapes, enabling fast identification and location in case of recalls or quality issues.

The key benefit of medical device traceability include:

Cognex vision solutions detect issues such as air bubbles, perforations, and reliably identify foreign objects, empty seals, and other defects that could compromise the integrity and sterility of medical device packaging.

These systems verify packaging, labeling, and sealing to ensure products arrive sterile, uncontaminated, and ready for use in doctor’s offices or operating rooms.

Únete y sigue nuestros artículos, promociones y novedades.