Get in touch

with an expert

Send us your contact information and we’ll contact you.

We offer custom industrial machine vision systems for part and material inspection, defect detection, and code reading to support traceability throughout your processes.

request a quote request a quoteCognex is a global leader in machine vision technology, renowned for its high-performance deep learning capabilities and unmatched quality in industrial vision systems.

A vision system is a tool that immediately enhances any manufacturing process, ensuring faster production, greater accuracy, and fewer defects—all at a reduced cost. These systems are frequently employed in industries that prioritize efficiency and product quality, including aerospace, automotive, metalworking, food and beverage, medical devices, general manufacturing, and packaging.

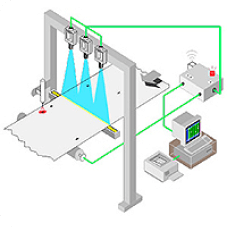

Machine vision systems rely on digital sensors housed within industrial cameras equipped with specialized optics to capture images. Software and hardware work together to process, analyze, and measure the properties of a product or part, which lets decisions be made in real time. Common applications include defect detection, quality control, part alignment, and reading barcodes or data matrix codes.

Here are some of the Cognex vision systems we offer:

Here are some of the vision sensors we offer:

Our Cognex industrial vision systems help optimize and automate your production by:

Industry is increasingly adopting Deep Learning technology to address inspection challenges in production lines that are too complex, variable, and costly for traditional rule-based algorithms.

Deep Learning mimics human perception more closely. It enables automation of previously unfeasible and highly complex applications, reduces error rates, and speeds up implementation times. AI in industry provides manufacturers with robust and reliable solutions for problems that challenge traditional machine vision applications.

[Project video with a client who sought to optimize their production lines]

1D Vision Systems

Focus on analyzing a digital signal line by line rather than processing the entire image.

2D Vision Systems

Perform area scans by capturing 2D snapshots at various resolutions.

Comparison between Area Scan and Line Scan:

Ideal for tight spaces, such as when the camera needs to be placed between conveyor rollers to view the base of a part.

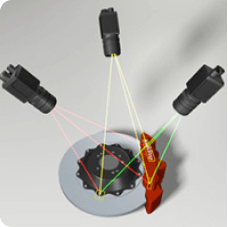

3D Vision Systems

Typically involve the use of multiple cameras or one or more laser displacement sensors.

Why Choose Vinssa?

Vision systems are devices that provide instant improvements in any manufacturing process, allowing products to be made faster and defects to be eliminated at a lower cost. They are mainly used in the food, medical, manufacturing, automotive, metalworking, aerospace, and packaging industries. These systems rely on digital sensors inside industrial cameras with specialized optics to capture images. Hardware and software then work together to process, analyze, and measure various characteristics to support real-time decision-making.

They prevent quality issues like missing or misassembled components, eliminate the need for human visual inspection, reduce inspection times, detect damaged products, and more.

The cost depends on several factors, with resolution being the most important—higher resolution lets you detect smaller defects. It’s essential to choose the right resolution for your application. Please contact us to tailor a solution that perfectly meets your needs and find the best option.

Cognex vision systems are enhanced by various components like lighting, lenses, light filters, vision processors, image sensors, and communications tools. Our offerings cater to four primary applications: guidance, identification, measurement, and inspection. If you require tailored recommendations or advice based on your specific needs, please feel free to reach out to us.

Existen: sistemas de visión 1D, sistemas de visión 2D, comparación entre escaneado de área y lineal y sistemas de visión 3D. Para más información contáctanos y con gusto asesorarte conforme a tus necesidades.

There are 1D vision systems, 2D vision systems, a comparison between area scan and line scan, and 3D vision systems. Contact us for more details and personalized guidance.

Vision systems are applied in many areas, including defect detection, assembly verification, character and code reading, and positioning for industrial robots. They are used wherever precise and automated visual inspection is needed.

captured visual data is analyzed using specialized algorithms and software to extract specific features, including presence, orientation, shape, size, and position. Based on this analysis, vision sensors can make informed decisions and execute tasks such as quality control, product inspection, object tracking, and pattern recognition, among various other industrial applications.

Lighting: This component illuminates the part or object, enhancing features for clear visibility by the camera.

Lens: The lens captures the illuminated image and focuses it onto the image sensor as light.

Image Sensor: This device converts the light received from the lens into a digital image, which is then sent to the processor for analysis.

Vision Processing Tools: These tools optimize and analyze the captured image, extracting relevant information and applying algorithms for inspection and decision-making.

Communications: This component transmits information to other devices using discrete I/O signals or serial connections, facilitating recording or usage during inspection.

Available types include 1D vision systems, 2D vision systems, line scan vs. area scan, and 3D vision systems. Choosing the right system is crucial to meet your specific vision application needs.

If you have discontinued equipment, there’s no need to worry! We provide a selection of spare parts to help keep your systems running smoothly. Moreover, we encourage you to explore our newer equipment versions, which are designed to further optimize your production line and ensure you stay at the cutting edge of efficiency and technology. Feel free to reach out for more information!

High-quality marking processes for automotive parts with minimal downtime, operating 24/7 all year round.

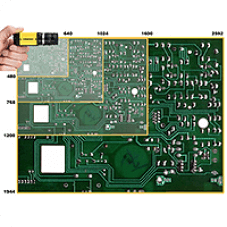

Marking of circuit boards to identify their components.

Verification of expiration dates and batch codes on vaccines and medications, ensuring compliance with necessary regulations.

Verification of expiration dates and batch codes on food and beverages, ensuring regulatory compliance.

Improving manufacturing quality and performance of consumer products with vision systems.

Long-distance code detection.

Inspection of assemblies with very small dimensions.

Únete y sigue nuestros artículos, promociones y novedades.